About British Bakels

British Bakels manufacture and distribute a wide range of high-quality bakery ingredients to the commercial bakery market. Some of which are tailor-made for Industrial and Instore Bakeries, while others are specifically developed for the Craft and Foodservice sectors.

Well established sales and technical teams get to the heart of customers’ operations and requirements, delivering first class support to maximise customers’ sales and efficiency.

Serving specific market sector requirements does not stop at product development and technical support. Diverse packaging formats and equipment to support product application are also tailored to ensure that customers, whatever their size, can simply and seamlessly use Bakels’ ingredients to produce top quality finished bakery goods.

Located in Bicester, Oxfordshire, British Bakels commenced production in 1990 and has continually invested in both people and facilities to produce industry-leading bakery ingredients and ensuring the sustainable growth of the business.

Baking Centre

The Baking Centre at Bakels’ site in Bicester, Oxfordshire, opened its doors in 2014 and boasts a wide range of state-of-the-art bakery equipment to serve a variety of different customers.

A presentation suite provides the perfect setting to work closely with customers to refine concepts and innovations, all underpinned by a deep understanding of key market trends.

From small customers trialling a range of applications, to large retail and industrial bakeries developing innovative, bespoke solutions, the Baking Centre provides the perfect facility for collaborative partnerships.

High Temperature Production Line

Investment in a high temperature production line allows Bakels to produce a range of True Caramels for the global market. The line consists of pressure/vacuum cookers and associated raw material supply, packing and cleaning equipment, allowing for controlled and consistent production quality time-after-time.

The investment comes as the global Caramel Ingredients market is forecast to grow by over 7% by 2021. The line also produces some of Bakels’ long established and successful products, adding significant capacity.

Near-Infrared Technology

Implementation of Near-Infrared Technology into the manufacturing process creates a unique profile for products and ensures each and every batch matches this, delivering customers complete piece of mind in the quality of products coming through their doors.

Optimised Packaging Solutions

Bakels’ packaging solutions enables customers to optimise efficiency, reduce wastage and enjoy simplicity in their production process.

Wet products such as sauces or icings supplied in sachets of between 150-2000g gives customers of different size suitable pack configurations to suit their needs.

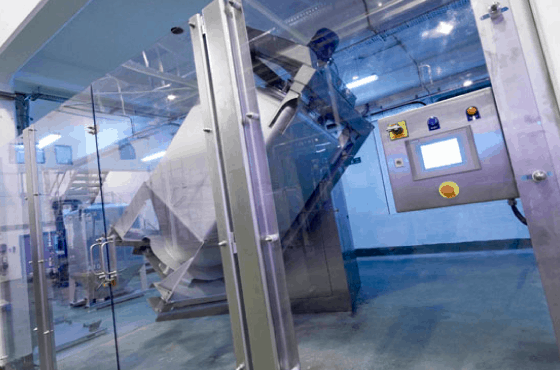

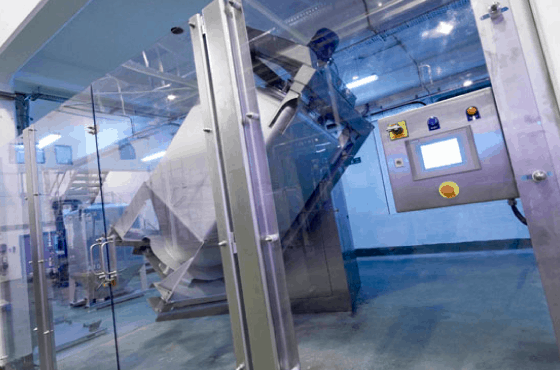

Matcon Mixing System

The tumble mixing system provides allergen segregation in the manufacturing process, crucial to the safe supply of a range of allergen containing products.

With a wide range of customers requiring bespoke ingredients, this system allows Bakels to produce mixes containing particulates such as chocolate chips and evenly distribute them in he product, giving customers consolidated bakery solutions.

Stevens Weighing Systems

A state-of-the-art weighing system allows fast and accurate weighing of raw materials into Bakels’ range of over 500 products.

This control enables customers to produce the same high quality finished bakery goods for their customers, delivering complete control and quality assurance down the supply chain.

Large Scale Distribution Centre

Investment in an 80,000 square foot, 10,000+ pallet, finished goods Distribution Centre near Bakels’ Bicester site significantly increases storage capacity and provides a sustainable foundation for future growth.